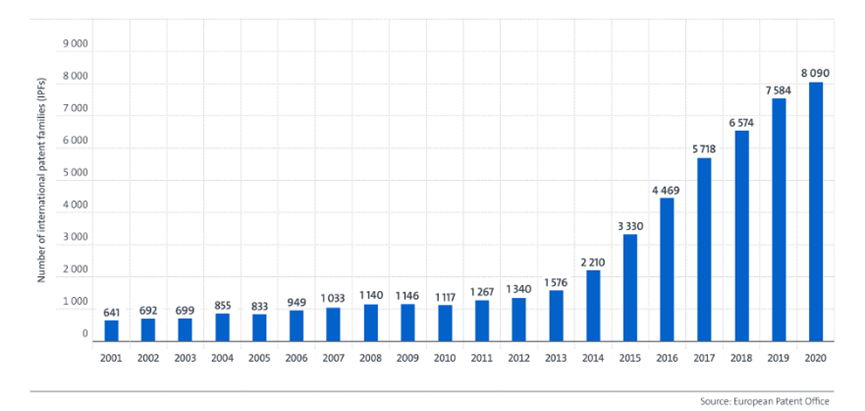

The European Patent Office (EPO) today released a report on "Innovation Trends in Additive Manufacturing". The report shows that from 2013 to 2020, the average annual growth rate of patent families in 3D printing technology was 26.3%, which is almost the same as all technologies in the same period. 8 times the total area (3.3%).

3D printing patent application trends

The market for 3D printing has also become more diverse. Previously the main players were established engineering companies, but now there are more start-ups and specialist additive manufacturing companies. Since 2001, there have been more than 50,000 3D printing patent families worldwide.

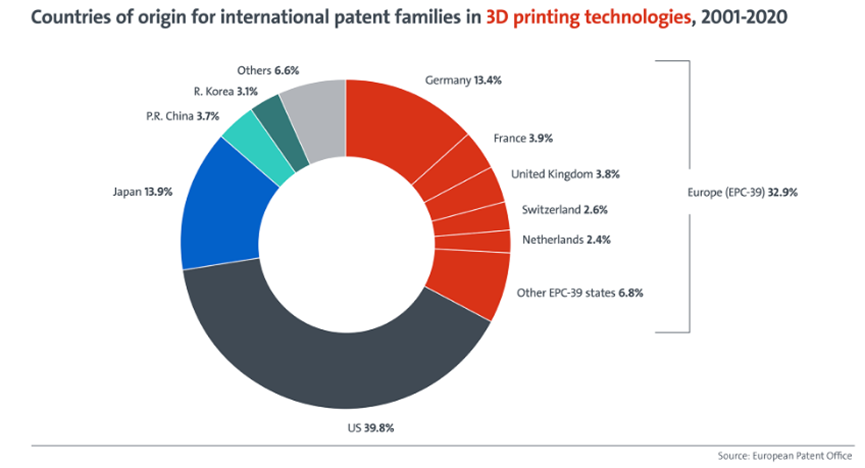

Europe and the United States lead the global 3D printing field. Between 2001 and 2020, the United States accounted for 39.8% of all patent families related to additive manufacturing. Europe follows closely behind with a 32.9% share. Europe and the United States together account for nearly three-quarters of global 3D printing innovation. Japan accounts for 13.9% of 3D printing patent families, China and South Korea account for 3.7% and 3.1% respectively. In Europe, Germany has emerged as the clear leader, accounting for 41% of the European share, while France is in second place with a 12% share.

National proportion of 3D printing international patent families from 2001 to 2020

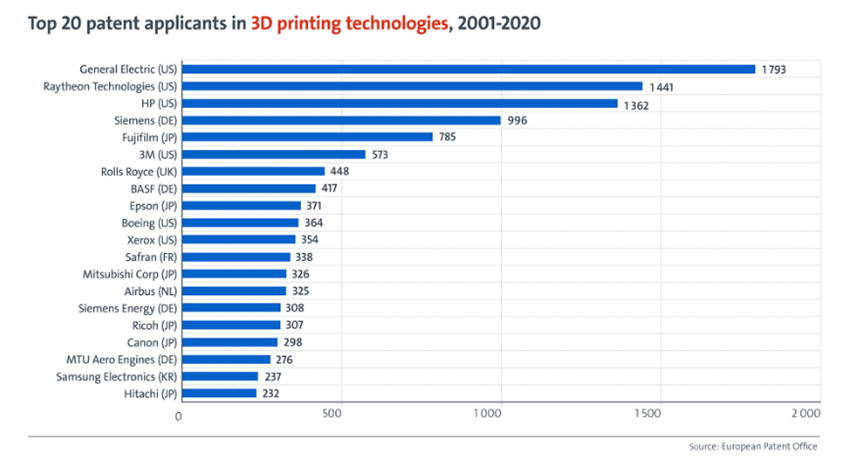

Companies from the United States, Europe and Japan have all entered the top 20 applicants for additive manufacturing patents, with General Electric, Raytheon Technologies and Hewlett-Packard in the top three. Siemens, ranked fourth, is the most powerful company in Europe, with nearly 1,000 patent families. While the top companies list is dominated by large engineering companies across a range of industries, the additive manufacturing innovation ecosystem is made up of several specialist 3D printing companies and vibrant start-ups, as evidenced by a variety of smaller entities in the EPO statistics.

Top 20 3D printing patent applicants from 2001 to 2020

Universities and public research institutions (PROs) have also made significant contributions to innovation in 3D printing. About 12% of 3D prints were submitted by universities or professionals. One-third of the patent families are related to biological materials, and one-half of the patent families are related to organs and artificial tissues, all from universities or professionals.

Five of the top ten universities, professionals or hospitals are located in the United States. But Germany's Fraunhofer Gesellschaft is in the clear lead, with 221 patent families. Taiwan's Industrial Research Institute (ITRI) is the only Asian institution in the top ten, which also includes two French research institutions, CNRS and CEA, and the Netherlands' TNO.

Additive manufacturing eliminates traditional technical constraints in industrial production processes, reduces waste, and paves the way for mass customization. It is no longer a niche technology and is transforming more and more industries. Since 2010, the health, medical and transportation sectors have attracted the majority of 3D printing applications. More and more materials, such as plastics, metals, ceramics, and even organic cells, are applying 3D printing technology. In the fields of tools, energy, fashion, electronics, architecture, and even food, the application of 3D printing technology is also growing rapidly.

Of the 10,000 patent families published between 2001 and 2020, approximately one-fifth are concentrated in the health and medical fields. Additive manufacturing is particularly suitable for patient-specific implants and anatomical models. Among patent applicants, a higher-than-average proportion of university, professional, and hospital applicants is due in large part to advances in 3D printing for medical applications. In the second largest industry, transportation, where additive manufacturing can be used to improve product development and volume production, there have been more than 7,000 patent families in the past decade.

Wohlers Associates estimates that the additive manufacturing market is growing strongly, with industry revenue tripling from $6 billion in 2016 to $18 billion (€16.17 billion) in 2022. During the epidemic, 3D printing has played a key role in shifting to local production and reducing reliance on international supply chains. Forecasts show that the market will exceed $50 billion by 2028.

联系咨询

| Get exact prices For the country / regionE-mail: mail@yezhimaip.com |